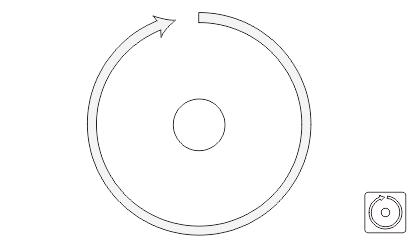

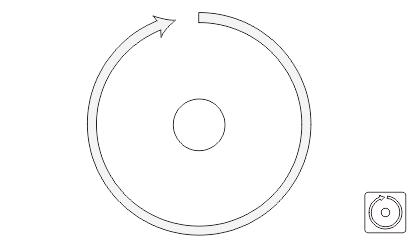

1、Indexing Drives

-

The indexing drives operate intermittently as follows: Dwell→AEIndex→AEDwell→AEindex.

-

Dwell: Output shaft stops rotating and cam follower touches the straight part of taper rib of roller gear cam.

-

Index: Output shaft rotates and cam follower touches the curve part of taper rib of roller gear cam.

-

Usually, the indexing drives dwells for a moment after input shaft rotates once and then output shaft indexes once.

-

After output shaft rotates, the indexing drives dwell. At this moment, the operators can decide the locations of theindexed products and start to work on processing, assembling and examining.

-

The rotary table on the output shaft can be used as the central driving power of the automatic rotary machinery.

-

While the sprocket or pulley is installed on the output shaft, the chain/belt-driven conveyer shall drive intermittently the in-line automatic machinery.

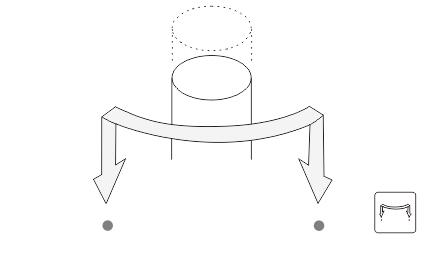

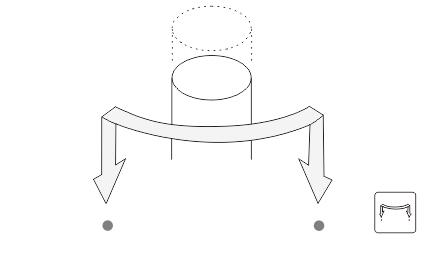

2. Oscillating Drives

-

When oscillating drives are in operation, the rotary input shaft with equal speed will make the output shaft rotate forward and backward.

-

Besides rotating forward and backward, the rotation central point and the rotation angle degree can be set to some extent.

-

Because there are two cam followers carrying one continuously operating taper rib, the sub-pressure generated from cam and the cam followers shall contribute to a good rotation and avoid backlash problems.

-

While an oscillating arm is installed on the output shaft and a roller in the front of the oscillating drives, the device can be guided to move forward straight and used as a transporting equipment.

-

If the oscillating drive is designed as an intermittent index equipment to rotate while indexing or dwelling, the stability and velocity of the machinery shall be increased.

3.Roller Drives

-

Roller drives is a kind of gear-down engine, providing stable rotation, no backlash and excellent torque.

-

Because the roller gear cam and the cam follower match each other while rotating, the machinery can operate efficiently.

-

In addition to as a gear-down machine, it can be also used as a device to determine the final position while indexing table.

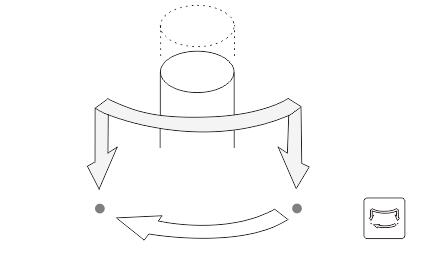

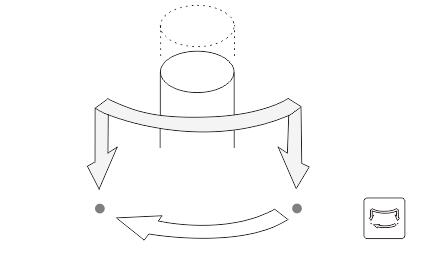

4.Oscilate Handler

-

When oscillating drives are in operation, the rotary input shaft with equal speed shall make the output shaft rotate forward and backward and lift in two dimensions.

-

The output shaft can be set to stop at the central point of rotation path while oscillating. The rotary angle degree and lifting capacity can be also set.

-

Oscillate handler, applying stereoscopic cams, can provide correct timing. Overlap of rotating and lifting and timing can be set.

-

The oscillate handler can make a transportation from conveyor to operation table.

5.Oscilate Handler

-

This motion is also three-dimensional motion, compared to the last motion, it doesn't backtrack by the same route, but move back on the low position, this motion can increase the work working

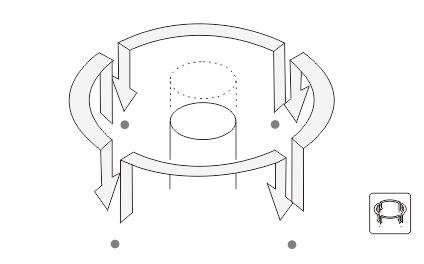

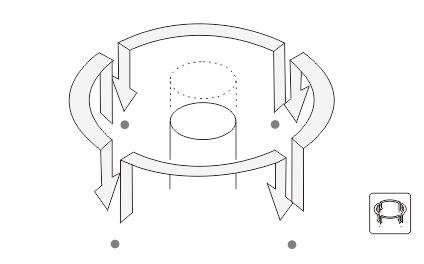

6.Index Handler

-

Index handler can rotate and lift in two dimension intermittently. The operation procedures are as follows: Dwell→AELift→AEIndex→AELift→AEDwell

-

Output shaft can be set to stop at the central point of rotation path while indexing intermittently. The rotary angle degree and lifting capacity can be also set.

-

Index handler, applying stereoscopic cams, can provide correct timing. Overlap of rotating and lifting and timing can be set.

-

Index handler can be used as a conveyer that can move along with the indexing direction and make other actions while transporting.

0577-62785710

0577-62785710 hicpu@hicpu.net

hicpu@hicpu.net

DS series cam indexers

DS series cam indexers DF series cam indexers

DF series cam indexers DT series cam indexers

DT series cam indexers DA series cam indexers

DA series cam indexers FN/FH series lift sway indexer

FN/FH series lift sway indexer HP series cam indexers

HP series cam indexers KAKD series cam follower

KAKD series cam follower